Stretch Film

Stretch film, also termed as stretch wrap is a plastic film that is highly stretchable and is used to wrap around different items. There are two main types of Stretch Films – Hand Stretch Film and Machine Stretch Film. Based on type, performance, size as well as budget, there are different types of stretch films available in the market to meet the specific requirements of the stretch film wrapping needs. Stretch films have resistance to pilferage, UV resistant with high tack strength and lower operating and maintenance costs compared to strapping.

Benefits of Stretch Film

1. Stretch Film Conveys Predominant Thing Assurance – These films keep the item free of dampness, residue and soil. The transportation harms are negligible. In the event that UVI (Ultra Violet Inhibitor) Stretch films are utilized it shields the thing put away outside from ultra-violet beams.

2. Stretch Films Are Financially Savvy – Stretch film wrapping is a superior option in contrast to lashing or warmth shrivels film. The machine, stretch wrap hardware, is more affordable contrasted with alternate options and furthermore as far as a measure of vitality devoured.

3. Stretch Film Is Proficient – The thing wrapped utilizing stretch films can be effectively looked over optics. Since its simple to wrap, the efficiency of the labourers increments. The stretch films can be reused. There are numerous sorts of wrapping films to suit your particular necessities. Here we take a gander at the different kinds of stretch films.

Types of Stretch Films

1. Blown Stretch Films – This kind of film utilized on high power items as they have prevalent cut obstruction. They look cloudy and dull and are extremely boisterous when you loosen up the film for wrapping. Air is introduced from an opening in the center of the die to blow up the film tube like a balloon. On top of the film tube, an air ring blows onto the film to cool it.

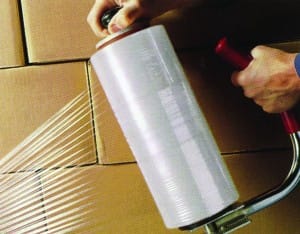

2. Hand Stretch Film – This film is also known as hand wrap, pallet wrap or hand stretch wrap. These films are usually used when the weight of the item is less. The reason is that hand wrapping is an extremely difficult task as it has to be done manually. If not done in an appropriate manner, it can cause damage to the items wrapped.

3. Converted Film – This sort of film is stretched before wrapping the item/thing. Changed over films are steady and solid as well as can be reused. Aside from that, very few upsets of the film are required to wrap the heap. This implies you spare time as well as maintain a strategic distance from wastage of film.

4. Cast Stretch Film – Also known as a cast film or cast wrap have astonishing optics, polished & have fantastic tear opposition. They have predictable thickness & stick. These films loosen up without noise. Air is introduced from an opening in the center of the die to blow up the film tube like balloon.

5. Machine Stretch Film – To wrap an item using this type of wrap film you need a stretch wrap machine. Some of the benefits of using machine Stretch film over hand Stretch film include the reduced material cost, ease of use and safety. Plus the items are better secured because of efficient packaging.