Metal, though strong and sturdy, is not immune to time and nature. Just like trust, even the hardest steel can corrode when exposed to the wrong environment. In the world of manufacturing and exports, protecting metal parts is not just a task—it’s a responsibility. Choosing the right packaging isn’t about wrapping a product; it’s about preserving its value, performance, and promise. This is where VCI film steps in—not just as a packaging material, but as a smarter, safer way to guard against rust and decay. Let’s explore how this modern solution is changing the way industries protect what they create.

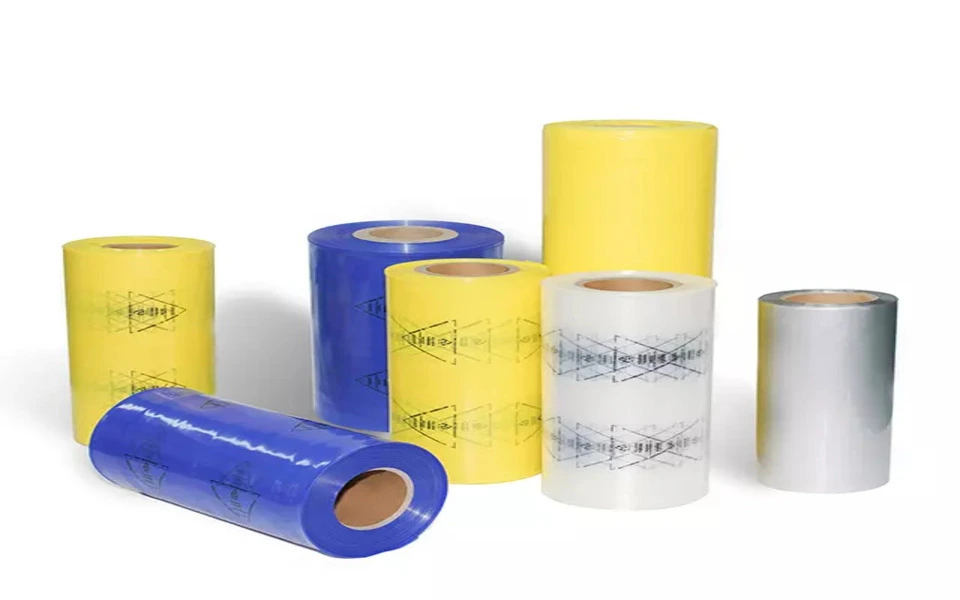

What Is VCI Film?

VCI means Volatile Corrosion Inhibitor. A VCI film is a special kind of plastic used to keep metal parts safe from rust. It contains corrosion-inhibiting compounds that release protective vapors over time. These vapors form a thin, invisible shield on the surface of the metal, which blocks out moisture, air, and other rust-causing elements. This protective action helps prevent corrosion during storage and shipping.

Why Is VCI Film Better Than Regular Packaging?

Here’s why more industries are switching to VCI film:

Rust-Free Guarantee

VCI film gives full coverage and forms a barrier that keeps metal parts rust-free, even during long shipments.

No Need for Oils or Grease

Traditional methods require oil coatings, which need cleaning later. VCI film works without extra steps. Just wrap and go.

Easy and Clean

Handling is mess-free. Workers don’t have to wear gloves or worry about staining the parts.

Saves Time and Cost

No need for applying or removing rust preventives. That means less labor, fewer materials, and lower costs.

Eco-Friendly Options

Many VCI films are recyclable and made with less toxic chemicals compared to other rust preventives.

Industries That Benefit from VCI Film

VCI film is widely used in:

- Automotive industry—for engine parts, gears, and bearings

- Machinery and tools—to ship parts safely

- Aerospace—for precision components

- Metal fabrication—for coils, sheets, and assemblies

How to Use VCI Film Properly

Using VCI film is simple but must be done correctly:

- Wrap the metal part fully so the VCI vapors can reach all surfaces.

- Seal the package tightly to trap the vapor inside.

- Store in a dry place, away from extreme temperatures or sunlight.

- Avoid contact with water or oil before packaging.

Final Thought

Everything built with care deserves to last. Metal parts are often the backbone of machines, vehicles, and tools that run our world. Leaving them unprotected is like letting time undo hard work. With VCI film, we’re not just fighting rust—we’re embracing a packaging method that respects the effort behind every piece of metal. It’s clean, reliable, and designed to make sure your product reaches its destination just as it left your hands—strong, untarnished, and ready to perform.