Advance Packaging Technology and Infrastructure

At Girdhar Roll Wrap, we have a sustainable packaging infrastructure designed to deliver best-quality packaging material. Our advanced facilities guarantee high-quality production of flexible laminates and surface protection films. Our infrastructure is the backbone of our success. The modern facility handles every step of production, from initial processing to final delivery.

We craft each product with care, prioritizing safety measures to ensure premium quality. Our skilled team handles operations, ensuring new ideas and maximum use in every item we produce. To keep our machines functioning properly, we update and repair them on a regular basis. Our well-stocked warehouses are always ready to meet market needs quickly.

We have organized our infrastructure into areas like manufacturing, quality control, and packaging. Every product passes strict quality checks based on Indian and international standards.

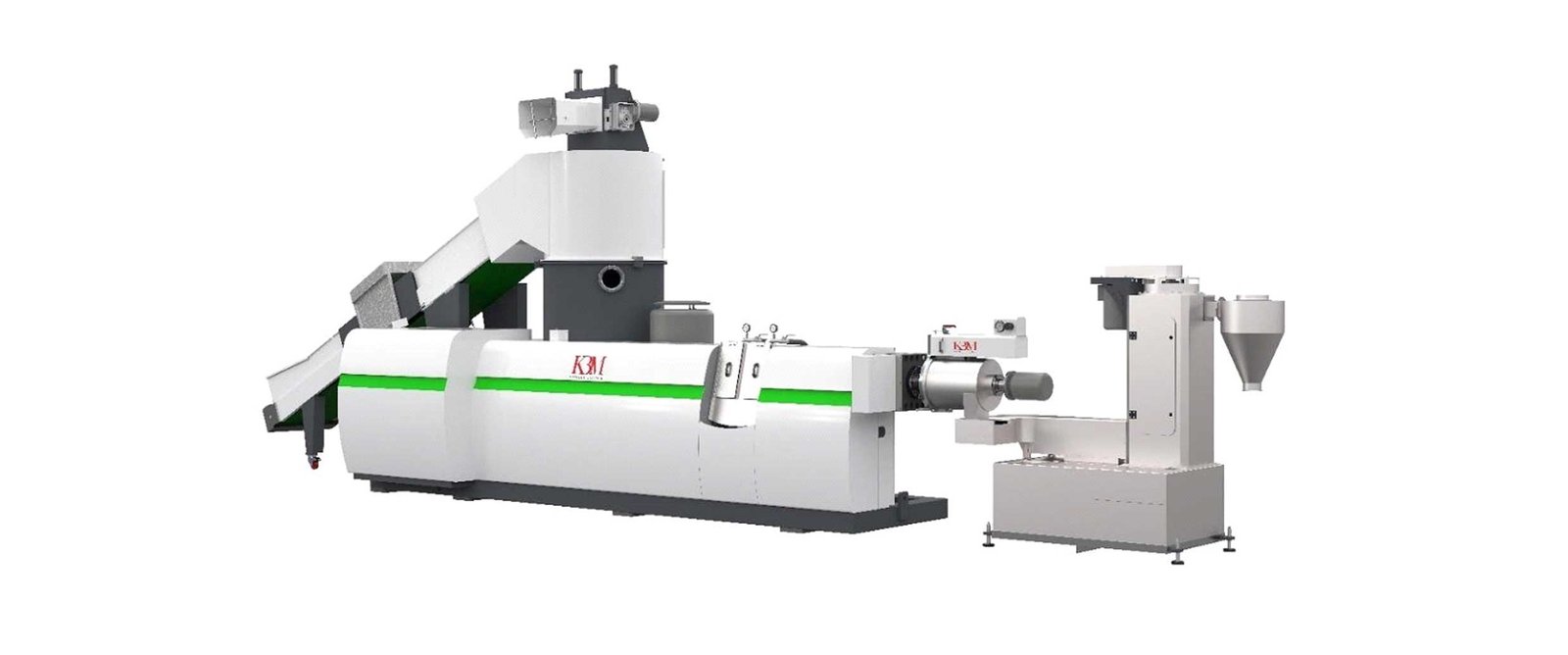

The recycling plant converts multilayer film waste into reusable granules, reducing our environmental impact.

We use advanced lab equipment to test materials and products. Our innovative packaging technology ensures protection and efficiency.

We leverage strong infrastructure and advanced technology to deliver quality and trust in every product. This commitment makes us the first choice in the industry.

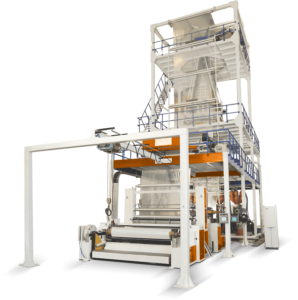

Multilayer Film Plant

- Film Width upto 850 mm

- 4 co – extrusion blown film plants

- Capacity 7200 metric tons/year

Printing machine

- Upto 8 Colour Rotogravure Printing

- Auto Registration Control

- Web Video defect detection system

- Printing Width: 1050mm

- Turnbar for reverse printing and coating

Lamination Machine

- Solventless Lamination

- Solvent based Lamination

- upto 1050mm width

Coating Machine

- Upto 3 color

- Printing width 2500mm

Inspection Machine

-

Every printed film goes through inspection

machine as part of our quality control process.

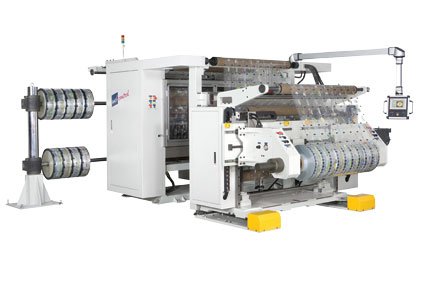

Slitting Machine

-

High speed and high quality slitting machine

with good tension control, ensuring trouble free

operation for rolls in FFS machines.

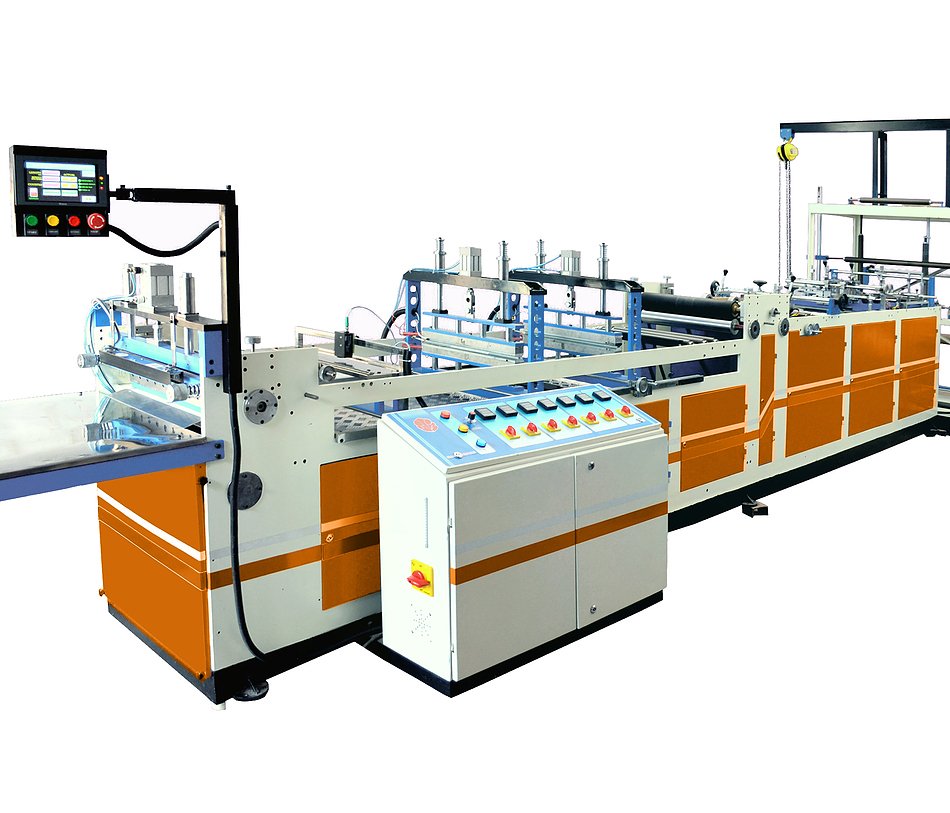

Pouching Machine

-

Multiple automatic pouching machines, allowing us

to produce all kinds of pouches. Such as zipper,

standup, side gusset, centre seal etc.

Recycling Plant

-

In order to reduce our carbon footprint,

we have a recycling plant which helps

convert multilayer film waste into granules for

further processing.

Lab Equipments

-

All our raw materials go through all

applicable tests before they go into production.

Similarly, all our products go through quality

tests before they leave our facility - A proficient testing lab