When we think about modern décor and manufacturing, one material often works silently behind the scenes—self-adhesive films. These versatile films are easy to apply, cost-effective, and come in different designs and finishes, making them useful for both homes and industries.

In this blog, we will explore what self-adhesive films are, their benefits, and how they are widely used in home décor and manufacturing.

What Are Self-Adhesive Films?

Self-adhesive films are thin sheets made of materials like PVC, polypropylene, or polyester with a pressure-sensitive adhesive on one side. They don’t need extra glue—just peel and stick.

According to a report by Markets and Markets, the self-adhesive film market is projected to reach USD 9.3 billion by 2027, growing steadily because of demand in décor, automotive, and packaging industries.

Benefits of Self-Adhesive Films

- Easy to apply – No professional tools or glue required.

- Cost-effective – Cheaper than traditional décor or protective methods.

- Customizable – Available in many textures, designs, and finishes.

- Durable – Resistant to scratches, stains, and moisture.

- Eco-friendly options – Many films are recyclable and reusable.

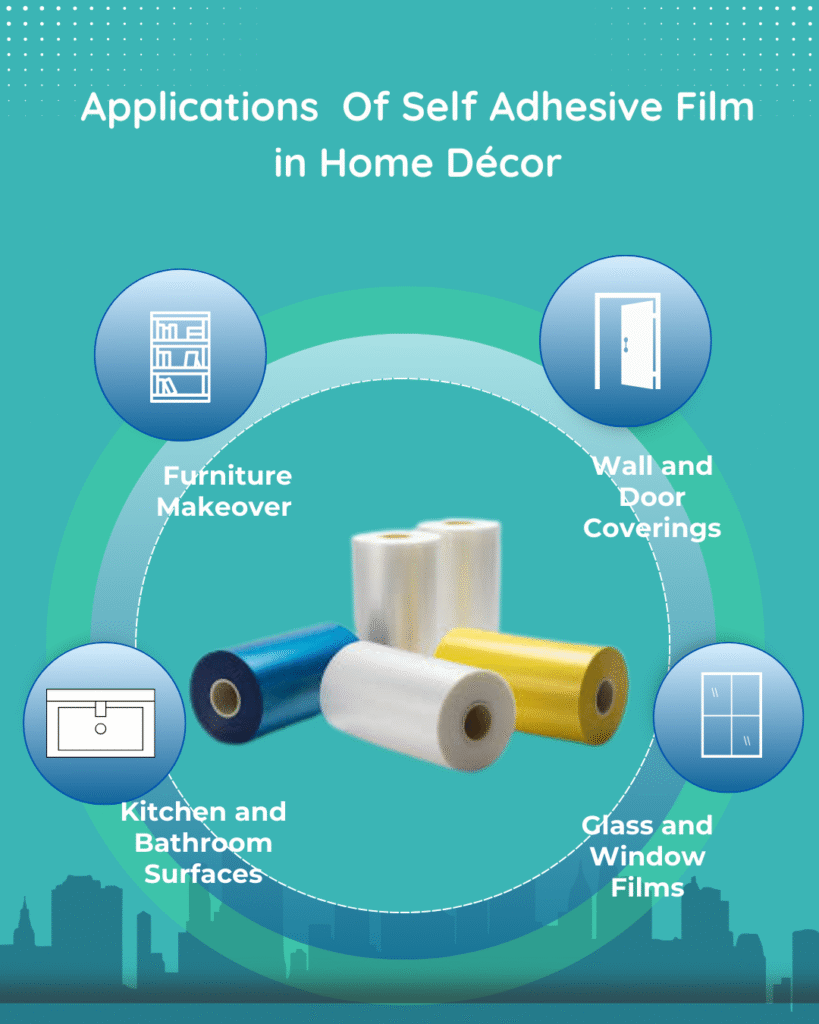

Applications in Home Décor

Self-adhesive films are popular in homes for giving spaces a quick upgrade without heavy costs. Some common uses include:

1. Furniture Makeover

Old furniture can look new with a layer of wood-grain or matte-finish self-adhesive film. Instead of buying new furniture, people often use films to refresh surfaces.

2. Wall and Door Coverings

Decorative films with patterns or solid colors are widely used as wallpapers. They are also applied on doors for a clean, modern look.

3. Kitchen and Bathroom Surfaces

Moisture-resistant films are perfect for countertops, cabinets, and bathroom shelves. They protect surfaces while adding a stylish finish.

4. Glass and Window Films

Frosted and tinted self-adhesive films are used on windows for privacy and UV protection, while also improving energy efficiency in homes.

Fact: The U.S. Department of Energy states that using reflective or tinted films on windows can reduce solar heat gain by up to 70%, cutting cooling costs in summers.

Applications in Manufacturing

In industries, self-adhesive films go beyond decoration. They play an important role in protection, branding, and efficiency.

1. Surface Protection

During transportation and assembly, films protect products like appliances, glass, and metals from scratches, dust, and damage.

2. Automotive Industry

Car interiors and exteriors use self-adhesive films for protection, lamination, and even styling. Paint protection films are a well-known example.

3. Branding and Labeling

Manufacturers use printable adhesive films for product labels, logos, and promotional stickers. They provide clarity, durability, and easy customization.

4. Electronics and Appliances

Films protect the screens of TVs, refrigerators, washing machines, and other appliances until they reach the customer.

Fact: The protective films market is expected to grow at a CAGR of 5.6% from 2023 to 2030 (Grand View Research), driven by demand in electronics and automotive sectors.

Why Self-Adhesive Films Are Here to Stay

The growing focus on cost efficiency, sustainability, and convenience makes self-adhesive films a preferred choice. Whether it’s a homeowner upgrading a kitchen or a manufacturer ensuring safe delivery of appliances, these films deliver value in every application.

Final Thoughts

Self-adhesive films are more than just decorative stickers—they are functional solutions for both homes and industries. From giving your furniture a new life to protecting delicate products during shipment, their uses are endless.

With the self-adhesive film market expanding globally, we can expect even more innovative applications in the coming years.

✅ Whether you’re revamping your living room or manufacturing consumer goods, self-adhesive films offer durability, design, and protection—all in one simple solution.