Aluminum has always been admired for its strength, elegance, and versatility. From sleek architectural facades to durable industrial panels, it blends beauty and function effortlessly. Yet, like anything valuable, it is vulnerable. Scratches, stains, dents, and dust can quietly take away its charm and shorten its lifespan. It’s a bit like life itself—we put effort into building something perfect, but without protection, time and the elements can leave their marks. That’s where protective film for aluminium panels steps in, acting like an invisible shield that preserves both the look and value of aluminum panels.

Why Aluminum Panels Need Protection

Aluminum is strong, but it’s not invincible. Whether in construction, transport, electronics, or furniture, aluminum panels face multiple threats during manufacturing, storage, transportation, and installation.

Some common causes of damage include:

- Scratches and abrasions from handling and moving.

- Dust and dirt that dulls the finish.

- Chemical stains from exposure to cleaning agents or pollutants.

- Fingerprints and smudges that leave marks on polished surfaces.

- UV fading when panels are left exposed to sunlight for too long.

Without protection, even minor damage can mean costly repairs, replacements, or loss of product value.

How Surface Protection Films Work

Surface protection films are thin, adhesive-backed layers specially designed to safeguard surfaces without altering their appearance.

For aluminum panels, these films:

- Create a protective barrier against scratches, dust, and stains.

- Absorb impact from minor knocks or abrasions.

- Shield against UV rays to prevent fading.

- Maintain the original finish—whether matte, brushed, or polished.

- Allow safe removal without leaving any adhesive residue.

Benefits of Using Surface Protection Films for Aluminum Panels

- Damage Prevention – Keeps panels safe from scratches and dents during manufacturing, transport, and installation.

- Cost savings: reduce waste and replacement costs.

- Time Efficiency – Eliminates the need for maintenance or re-polishing.

- Better Aesthetics – Ensures the panels look brand new until they reach the final customer.

- Versatility—Works for various finishes and coatings on aluminum surfaces.

- Easy Application and Removal – Saves time for workers and ensures no adhesive marks.

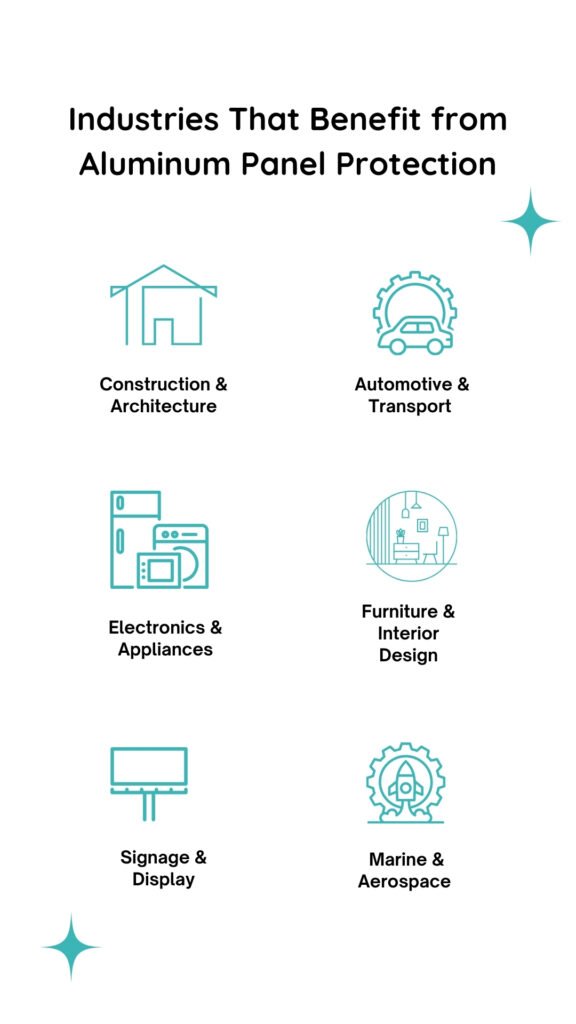

Industries That Benefit from Aluminum Panel Protection

Surface protection films are widely used in various industries:

- Construction and Architecture – For exterior cladding, curtain walls, and decorative panels.

- Transport and Automotive – To protect vehicle body panels and interior trims.

- Electronics – For aluminum casings in appliances and gadgets.

- Furniture and Interior Design—For high-end aluminum surfaces like kitchen cabinets or partitions.

Choosing the Right Surface Protection Film

When selecting a protection film for aluminum panels, consider:

- Adhesive Strength—Strong enough to stay in place but easy to remove.

- Thickness—Thicker films provide more impact resistance.

- UV Resistance—Important for outdoor applications.

- Temperature Tolerance – For environments with extreme heat or cold.

- Custom Sizing—To fit your specific panel dimensions.

Final Thoughts

Protecting aluminum panels is not just about preserving their appearance—it’s about respecting the effort, skill, and resources that went into creating them. Every scratch avoided is a silent win for quality.

In a way, applying a surface protection film is like taking care of the things we value in life. We can’t control every challenge the world throws at us, but we can prepare, shield, and ensure they reach their full potential without losing their beauty.

So, whether it’s for a skyscraper facade or a finely crafted piece of furniture, remember—protection today means perfection tomorrow.