Freshness is more than just a taste—it’s a feeling. It reminds us of early mornings, the smell of warm bread, and the comfort of a glass of milk after a long day. These days, food travels a long journey—from farms to factories to our plates—and keeping it fresh along the way is a real challenge. That’s where multilayer film packaging comes in, offering smart protection throughout the process.

Just like layers of experience shape our life, layers in packaging protect, preserve, and present food in its best form. Especially for dairy and bakery items, where every second of exposure matters, multilayer films have become the first choice for manufacturers and consumers alike.

What is a multilayer film?

Multilayer films are made by joining several layers of different plastic materials to form one strong and functional film. Each layer has a specific function—such as protection, sealing, or barrier control. These films are usually made using co-extrusion or lamination techniques.

Common materials used:

- Polyethylene (PE)

- Polypropylene (PP)

- Polyamide (PA)

- EVOH (Ethylene Vinyl Alcohol)

These materials are layered to create packaging that is strong, flexible, and airtight.

Why Multilayer Films for Dairy Products?

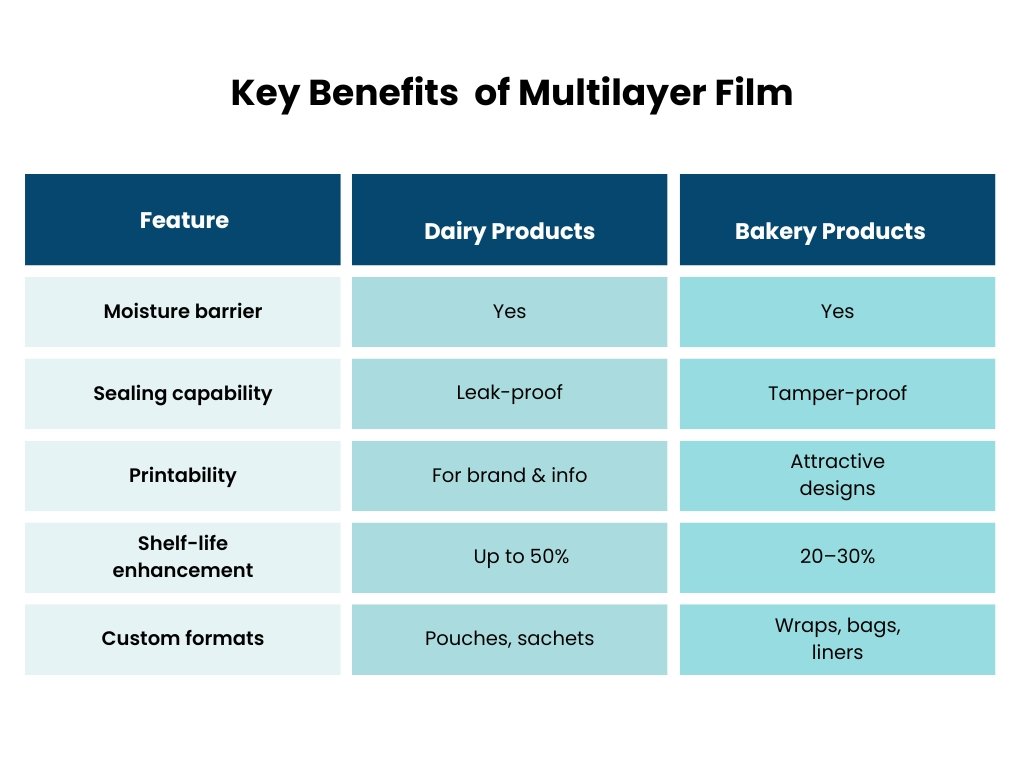

Milk, cheese, yogurt, and butter are quick to spoil when they come in contact with light, air, or moisture. Multilayer films act as a strong shield, keeping them fresh and safe. The advantages of multilayer film are as follows:

1. Excellent Barrier Properties

According to research from ScienceDirect, multilayer films can reduce oxygen transmission rates (OTR) to as low as 0.01 cc/m²/day. This is crucial for products like milk and cheese, which spoil quickly when exposed to air.

2. Extended Shelf Life

By blocking oxygen and moisture, these films help extend the shelf life of dairy items by up to 50%, as per data published in Packaging World.

3. Leak-Proof Sealing

Dairy products need secure packaging to avoid spillage. The inner layer of multilayer films allows tight and hygienic sealing, which keeps the product safe during transport.

4. Resistance to Puncture

Dairy packs often go through multiple handling points. Multilayer films have high tensile strength, which prevents tears or leaks.

Why Multilayer Films for Bakery Products?

Bread, cookies, and cakes can lose their quality due to air, moisture, or germs. Multilayer films help prevent this in the following ways:

1. Moisture Control

Multilayer films have outer layers that prevent moisture entry. This keeps bakery products crisp or soft as needed, depending on the type of product.

2. Aroma Retention

No one likes stale-smelling cookies. These films help retain original aroma and freshness, improving customer satisfaction.

3. Customizable Printability

Multilayer films offer high-quality printing surfaces, perfect for branding. This helps bakery brands stand out on shelves.

4. Convenient Packaging Options

From flow wraps for cakes to pouches for cookies, multilayer films support various packaging formats.

Industry Data & Trends

- The global market for multilayer films is expected to grow to USD 9.4 billion by 2027, with an annual growth rate of 6.2%. (Source: MarketsandMarkets)

- Over 60% of dairy packaging in India now uses multilayer films due to their protective qualities and cost efficiency.

- According to the Indian Packaging Institute, bakery brands using multilayer films saw a 15-20% drop in product returns due to spoilage.

Environmental Aspect

Modern multilayer films are becoming more sustainable. Some films now use:

- Recyclable structures (like mono-material PE-based layers)

- Biodegradable alternatives

- Recycled content layers

India is also seeing a rise in recyclable multilayer packaging, with FSSAI and CPCB encouraging sustainable material use in food packaging.

We often don’t notice the little things that make our daily life easier—like the packaging that keeps our food fresh. But behind that layer lies science, innovation, and care.

Multilayer films aren’t just packaging materials—they’re silent guardians of taste, quality, and trust.

In a world where change is constant and freshness is fleeting, multilayer films help preserve what truly matters—the essence of food. And perhaps, that’s a reminder that with the right layers of protection, everything—even the simplest loaf of bread—can stay whole, safe, and just as it was meant to be.