Every surface tells a story. When polished, smooth, and shining, it reflects perfection; when scratched, it silently reminds us of neglect. Aluminium Composite Panels (ACP sheets) are no different. They are trusted in modern architecture for their elegance and durability, yet their beauty is fragile during the journey from factory to final installation. One careless move, one scratch, and their charm fades. Protecting ACP sheets during transport and installation is not just about keeping a surface safe — it is about preserving the effort, cost, and vision invested in every project.

Why Protecting ACP Sheets Matters

Scratches on ACP sheets are more than just marks on the surface. They can:

- Spoil the overall finish of a building or project.

- Reduce the durability of the panel.

- Lead to extra replacement and repair costs.

- Create dissatisfaction among clients.

This makes prevention during handling, transport, and installation a crucial part of the process.

Common Reasons for Scratches on ACP Sheets

- Improper stacking—when panels are stacked unevenly or without protective layers.

- Friction during transport—Constant movement of panels against each other or against vehicle walls.

- Dust and debris—Sharp particles that rub against the surface.

- Wrong handling methods – Dragging or lifting panels without proper support.

- Lack of protective film—Panels without surface protection are highly prone to damage.

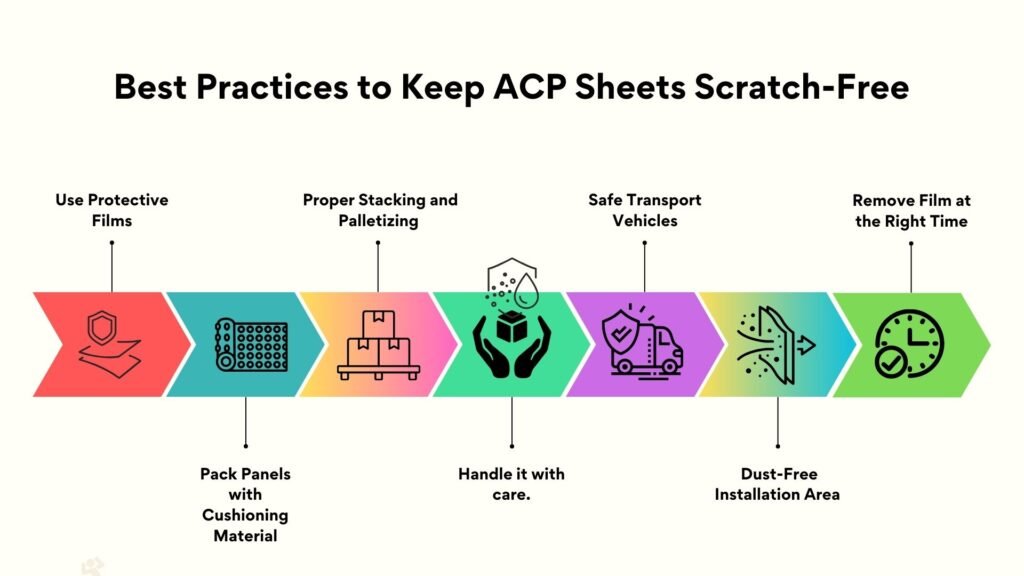

Best Practices to Keep ACP Sheets Scratch-Free

1. Use Protective Films

Covering ACP sheets with a surface protection film is one of the most effective ways to prevent scratches. These films act as a shield against dust, friction, and accidental marks during movement and installation.

2. Pack Panels with Cushioning Material

Always pack ACP sheets using foam sheets, bubble wrap, or corrugated boards. This reduces direct contact between panels and prevents friction.

3. Proper Stacking and Palletizing

- Place panels vertically or in flat stacks with separators between them.

- Use wooden pallets for safe transport.

- Avoid overloading to reduce pressure damage.

4. Handle it with care.

- Always lift panels with clean gloves to avoid fingerprints and scratches.

- Never drag sheets on the floor.

- Use proper lifting equipment for large panels.

5. Safe Transport Vehicles

- Use vehicles with smooth flooring and protective lining.

- Secure the load tightly to prevent movement during transport.

6. Dust-Free Installation Area

During installation, keep the working area clean. Dust, sand, or small debris can easily scratch the surface when panels are adjusted.

7. Remove Film at the Right Time

Do not remove the protective film too early. Remove it only after installation is complete to keep the surface safe till the final stage.

Additional Tips

- Store ACP sheets in a cool and dry place before installation.

- Avoid exposing them to direct sunlight for long hours while still covered with protective films, as heat can affect the adhesive.

- Train workers on safe handling methods to reduce careless damage.

Conclusion

Every scratch on an ACP sheet tells a story—a story of care missed. Just as life teaches us to protect what we value, ACP sheets too need thoughtful handling. From transport to installation, small protective measures ensure that these panels shine in their full glory without a single mark. Protect them well, and they will reflect beauty for years to come.

Keeping ACP sheets scratch-free during transport and installation is not just about saving costs; it is about respecting the craft, the effort, and the promise behind every panel.