When buying a new home, smart homeowners protect their investment. They use surface protection film (SPF) to safeguard furniture and flooring from scratches and damage during moving and renovation. These films also shield appliances, countertops, and sinks, preventing costly repairs. By acting proactively, homeowners keep their dream home pristine and beautiful for years.

What is a Surface Protection film?

Surface Protection Film (SPF) is a thin, adhesive-backed shield that safeguards surfaces from damage, scratches, and contamination. They are made from materials like polyethylene, polypropylene, and other polymers that offer durability and ease of use. These films are designed to be removed without leaving residue, preserving the surface’s quality and appearance.

In this blog, we’ll explore how surface protection films are used in different industries.

Automotive Industry

In the automotive industry, surface protection films play a crucial role in maintaining vehicle appearance and quality. These temporary films shield vehicles from scratches, dust, dirt, and minor damage during manufacturing, transportation, and display. This ensures the vehicle reaches customers in perfect condition, preserving its finish. Surface protection films safeguard vulnerable vehicle areas—body panels, bumpers, mirrors, headlights, dashboards, screens, and taillights—from damage. These films are applied to protect your vehicle’s sensitive surfaces against everyday wear and tear.

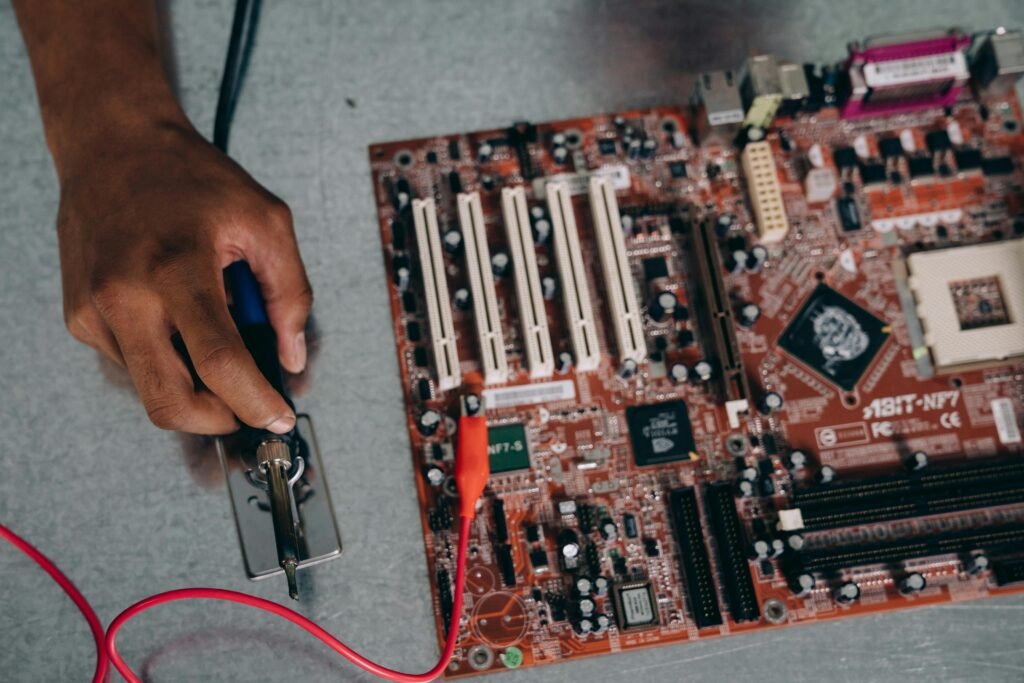

Electronics Industry

In the electronics industry, special protective films are used to shield sensitive parts like screens, glass panels, and metal surfaces during manufacturing and shipping. These films, known as Surface Protection Films (SPF), prevent costly electronic devices from getting damaged. Thanks to SPF, high-value electronics like smartphones, tablets, TVs, monitors, and home appliances remain scratch-free and intact until they reach consumers.

Wooden furniture

Protection films play a key role in maintaining the quality and appearance of various products. Furniture items, particularly those with delicate finishes or polished surfaces, are susceptible to scratches, dust, and other types of damage during manufacturing, transportation, and storage. Surface protection films provide a temporary protective barrier. That preserves the finish and look of furniture, ensuring that each piece reaches the customer in perfect condition.

Protection Films protect various surfaces from damage and scratches. These films are ideal for wooden furniture, glass, mirrors, and metal furniture, preserving their quality and appearance.

Renewable Energy Industry

In the solar energy industry, these films are applied to solar panel surfaces. They help to shield them from dust, dirt, UV rays, and weather conditions, all of which can reduce efficiency over time. The films help maintain the panel’s clarity, allowing maximum sunlight absorption and power generation.

In the wind energy sector, surface protection films are used on turbine blades to protect against erosion, impacts from debris, and harsh weather. This layer helps to extend the life of the blades and reduce maintenance costs.

Protection films enhance the durability, performance, and reliability of renewable energy systems. This enables the industry to maintain its focus on sustainability and efficiency.

Aerospace and Defense Industry

Protection films are essential for preserving the integrity and functionality of high-value components. Aircraft and defense equipment are frequently exposed to harsh environmental conditions, including UV rays, extreme temperatures, and physical impacts. These films help protect sensitive surfaces, such as aircraft windows, body panels, and electronic displays, from scratches, dust, and chemical exposure during manufacturing, transportation, and maintenance.

For defence vehicles and equipment, protection films shield crucial components from the elements, helping extend service life and ensuring operational readiness. These films also play a critical role in safeguarding delicate electronics and sensors from contaminants and damage during assembly and deployment.

Packaging Industry

These films are often applied to the surfaces of packaging materials, such as flexible films, cardboard, plastic, and metal containers, to prevent scratches, scuffs, and dust accumulation. This ensures that the packaging remains pristine and appealing when it reaches consumers.

They also play an important role in food packaging, where protective films maintain hygiene by preventing contaminants from reaching the product’s surface. In the printing process, these films protect custom graphics, logos, and colours on the packaging, ensuring that branding remains vibrant and visually attractive.

Pharmaceutical Industry

These films are used on packaging for medicines, medical devices, and sensitive materials to prevent contamination, dust, and scratches. Blister packs, bottles, and cartons use protective films to stay secure during transport, storage, and handling. Protection films are applied to sensitive equipment, such as lab surfaces, screens, and control panels, shielding them from chemical spills, dust, and scratches. This helps maintain a sterile environment, which is essential for producing safe pharmaceuticals.

Surface protection films are vital across industries, offering reliable defense against scratches, dust, and damage. From shielding furniture and electronics to preserving renewable energy systems and packaging, their benefits are undeniable. By using these films, businesses enhance product durability, reduce maintenance costs, and deliver quality to their customers. Protecting surfaces isn’t just practical—it’s essential for maintaining value and appearance.

Want to extend the life of your products? Girdhar Roll Wrap offers top-quality surface protection films to keep them safe and flawless!